Experts agree: For long-lived asphalt pavements and overlays, bond them with a well-placed bond or “tack” coat. But in practice, they’re not applied consistently, compromising the long-term performance of the bituminous surfacing.

Understanding and correct placement of bond or tack coats is essential for long-lived asphalt pavements. New research underscores the importance of bond coats, and new materials are changing how these essential placements are formulated.

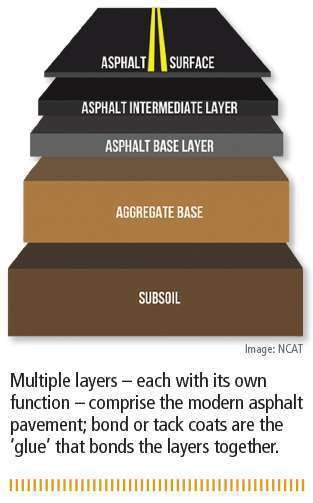

They’re better known as tack coats, but “bond coats” better describes their function. The purpose of a bond coat is to “glue” an asphalt overlay to the asphalt layer below.

Today – according to the Asphalt Pavement Alliance – some 94 percent of America’s roads are surfaced with asphalt. But if a strong bond is not created between the layer on which the asphalt driving course is placed, be it asphalt or concrete, the new asphalt surface is at risk of failure.

Bond, or “tack” coats provide the adhesive that binds the asphalt layer to the substrate, adding strength the same way flimsy, thin laminates of lumber are glued together to create strong plywood boards.

“Normally, when a new layer of hot-mix or cold-mix asphalt is placed, the surface of every rock and grain of sand is uniformly coated with a film of asphalt,” reports the Cornell Local Roads Program in New York State. “The initial film thickness is only a couple thousandths of an inch thick. Over time, sunlight hardens the surface film and makes the asphalt less sticky. Traffic abrades the surface, and water helps to remove the coating. In one or two years the asphalt film is worn off the surface, leaving the aggregate exposed.

“From that point forward, there is nothing there to bond a new layer of asphalt concrete to the old one,” the Cornell report says. “A tack coat replaces the worn-away asphalt and promotes bonding with the old pavement.”

Well after the contractor has departed the scene, poor bonding between two layers of hot mix asphalt becomes the cause of many pavement headaches. “Pavement bonding is essential to quality pavement performance,” says Dave Johnson, regional engineer, The Asphalt Institute. “Selection of an appropriate tack coat material, applied in the recommended ranges, provides the glue necessary to the pavement for bonding.”

Like plywood, asphalt pavements are built of layers, and their bonding is critical to good performance. “Building asphalt pavements in layers provides a number of advantages, [as] each layer can be engineered to have specific characteristics and properties,” reports the National Center for Asphalt Technology (NCAT) in spring 2015.

For example, surface layers may be designed to provide high levels of friction, be porous to drain water and eliminate hydroplaning, and optimized to provide a low levels of tire/pavement noise, NCAT says. Other examples of specific layer designs include those that are highly crack resitant and others that provide structural stiffness.

Regardless of function, if the layers are not bonded together, the interface between layers becomes the weak link in the system, and the pavement will not perform as intended. “Although we can design, construct and rehabilitate each layer independently, the layers must be bonded together for the pavement to respond to loads as intended,” NCAT says. “That is the purpose of tack coats.”

If layers are insufficiently bonded, the driving or friction course may begin disintegrating. A commonly observed problem related to poor bond between layers is slippage failure, which may occur at locations where traffic accelerates, decelerates or turns, reports NCAT. Other ills include delamination and a type of alligator cracking.

“Alligator cracking may be perceived as a bottom-up fatigue distress, when in fact the damage may have initiated at the poorly bonded interface,” NCAT advised. “Highway agencies should routinely core pavements in need of rehabilitation to determine if poor bonding is contributing to pavement deterioration.”

Bond coat application

A tack coat is sprayed on the surface of an existing asphalt or concrete pavement by a distributor truck immediately prior to placement of an overlay. The goal is to achieve uniform coverage over the entire surface to be paved. Once the tack coat is in place it should be given time to cure and become tacky. Normally this would only require a few minutes.

To preclude getting dust and dirt on the surface, traffic should not be allowed on the surface; in fact doing so will lead to residual asphalt being tracked onto adjacent surfaces, removing it from the path of the overlay and contaminating nearby areas.

Careful surface preparation is stressed by the Virginia DOT in its Asphalt Field Certification Study Guide. “For mix laid on top of existing asphalt layers, that surface should be properly prepared, [with] potholes filled, cracks sealed, and the surface cleaned,” the guide says. Virginia requires the use of a tack coat to ensure a bond between the existing pavement surface and the new asphalt overlay, unless exempt per specification.

The bond coat should not be used in lieu of removal of dust and dirt by brooming, or by flushing with air and water, the commonwealth states. It adds the tack coat material – which is normally asphalt emulsion but can also be liquid asphalt cement – must be placed by a pressure distributor, and all nozzles on the distributor must be fully open and functioning, and should be turned at the same angle to the spray bar, approximately 30 degrees.

In addition, Virginia requires the spray bar should be at the proper height above the pavement surface to provide for a double or triple overlap of the sprayed material. “The result will be the proper amount of overlap between the nozzles, and a uniform application of the tack coat to the road surface,” says the state agency. “The tack coat material should be heated to the proper temperature, so that it is fluid enough to be sprayed uniformly from the nozzles instead of coming out in strings.”

The coat should be uniform from edge to edge, but some pavement may show through. “If the correct amount of tack coat is sprayed on the surface, some of the existing surface will still be visible through the tack coat,” says Virginia DOT. “Not all of the existing pavement surface will be covered.” Available materials and existing site conditions will help determine the application rate and required amount of ultimate residual asphalt.

Materials for bond coats

Bond or tack coats are placed using either straight liquid asphalt, cutback asphalt, or asphalt emulsions. emulsifiers, water, and sometimes petroleum diluent to produce emulsified asphalt.

After 2000, there has been a shift from using “cutback” asphalts to using asphalt emulsions or liquid asphalt for tack coats. More recently, asphalt emulsions have been introduced that are engineered for higher performance, such as not tracking by tires onto adjacent surfaces.

Cutback asphalts: Liquid asphalt may be thought of as the viscous goo that remains after lighter hydrocarbons like naphtha, gasoline and kerosene are removed from raw crude oil at a refinery.

A cutback asphalt is made by mixing the liquid asphalt with a lighter hydrocarbon diluent – such as kerosene – so the liquid asphalt is more fluid and suitable for placement as a tack coat. While they still are commonly used, there are environmental concerns with their use, since they cure via evaporation of the lighter hydrocarbons and introduce volatile organic hydrocarbons to the atmosphere. Because of this, most DOT specs specify tack coat materials, application methods and payment – usually requiring the use of diluted asphalt emulsions.

Cutbacks are classified according to the speed of evaporation of the petroleum diluent, as in rapid curing (RC), medium curing (MC), and slow curing (SC) cutbacks.

Emulsified asphalts: On the other hand, an asphalt emulsion for bond coats or surface treatments is a homogeneous mixture of two insoluble substances, oil and water. In it, particles of liquid asphalt (the dispersed phase) are surrounded by molecules of water (the continuous phase). Compared to hot liquid asphalt, asphalt emulsions have greatly reduced viscosity, are safe to use at lower temperatures, and allow expensive liquid asphalt to be spread more thinly, perhaps saving money.

Emulsified asphalt is produced by dispersing tiny globules of asphalt cement into water treated with a small quantity of emulsifying agent. The dispersion takes place in a powerful blender, called a colloid mill, where spinning blades break or shear the liquid asphalt into suspended microdroplets, making emulsions as fast as 28,000 gallons per hour for asphalt emulsions, or 15,000 gallons per hour for polymer modified asphalt emulsions.

The emulsifier – commonly a surfactant (detergent) or surface-active agent – maintains the microscopic asphalt droplets in a stable suspension within the water, keeping them from recombining. Emulsifiers also control the “break” time following placement on a road, in which the water evaporates, leaving the asphalt behind. These are categorized as rapid setting (RS), medium setting (MS), slow setting (SS) and quick setting (QS) emulsions.

To make sure the asphalt adheres to the surface on which it’s placed, the emulsifier must be matched to the right aggregate. Igneous rock of silicate mineralogy like granite, trap rock or basalt generally are negatively charged, and react best with a cationic (positive) emulsion; positively charged sedimentary rocks of carbonate mineralogy like limestone or dolomite react best with an anionic (negative) emulsion. “The anionic grades are slightly preferred where limestone and dolomitic aggregates are exposed on the old road surface,” reports the Cornell Local Roads Program. Cationic grades would be preferred for all other aggregate types.

Either way – whether cutback or emulsion – once the liquefied asphalt cement is applied during road construction, the diluent petroleum solvent (in the case of asphalt cutbacks) or water (in the case of asphalt emulsions) evaporates, leaving the residual asphalt cement to do its job.

Modified bond coats

A new generation of modified bond coats is resulting in better-performing pavements, or bond coats that are easier to work with in the field, albeit at a higher price.

Lab devices have been developed that measure the degree of bonding that different bond coats achieve between lifts of asphalt, and the asphalt or concrete substrate, and have documented the better performance of modified emulsions. For example, using a direct shear test device, researchers for the Illinois Center for Transportation found use of a polymer modified binder tack coat increased the number of cycles to failure in the laboratory tests.

Manufacturers have stepped into the fray. For example, an “enhanced bonded pavement” has a uniform application of a modified tack coat beneath an overlay, providing a high bonding capability and other enhanced mix properties. The tack may be conventional but is usually a polymer modified asphalt emulsion.

In addition to higher bonding potential, this value-added bond coat can even result in a placement of a thinner asphalt layer, with associated savings, with performance equal to or superior to a conventional overlay due to the superior bond. “By increasing bonding by 25 to 75 percent, lift thicknesses can be decreased by 0.5 in., and [will] result in increased pavement life by 21 percent,” says Todd Thomas, Colas Solutions, in his 2011 presentation, Tack Coat Materials and Methods for Optimizing for Thin HMA Applications.

Tracking of tack coats by tires from the paving lane into adjacent lanes or streets, or by shoes into places of business, has been a bane of asphalt overlay projects. But the advent of value added “track-free tack” products has reduced this problem.

One such product is UltraFuse Bond Coat, from Blacklidge Emulsions, Inc. It’s a hot-applied (300+ degree), polymer modified, non-tracking asphalt bond coat that is designed to be applied with conventional asphalt distributors at rates of 0.08 to 0.18 gallons per square yard.

This high application rate becomes trackless to the touch in less than 20 seconds and is immediately ready for a hot or warm mix asphalt overlay, the manufacturer says. “The trackless behavior avoids pick-up on vehicles and construction equipment, keeping the heavy application in the intended area for overlay construction,” Blacklidge says. “When overlaid with HMA, the heat from the new asphalt layer reactivates the coat and creates the strongest possible bond between the new and old pavement layers.”