Forensic Studies Give Clues to Pavement Failure

By Tom Kuennen, Contributing Editor

Whether the pavement is black or white, flexible or rigid, asphalt or concrete, pavement forensic testing is the key to preventing future pavement failures in either paving medium.

In the lab or in the field, engineers examine pavement condition, cores or entire cut-out sections to ascertain what went wrong, and why.

“Forensic pavement analysis is a core function of every department of transportation,” say Paul E. Krugler, Carlos M. Chang-Albitres and Robert L. Robideau, Texas Transportation Institute, in their paper Development of a Rigid Pavement Forensics Knowledge Management System to Retain TxDOT Corporate Knowledge.

“Excellence in this technical area allows selection of proper and most cost-effective rehabilitation options, with potential monetary benefits to the department of millions of dollars annually,” they write. “Capturing and disseminating corporate forensic pavement knowledge will help assure exceptional performance in this area in the future.”

Acknowledging that staff turnover and retirements were depleting the acquired engineering expertise of Texas DOT, the writers in 2005 outlined creation of a knowledge database of rigid (portland cement concrete), and later, in 2007, flexible (bituminous concrete) pavements, all accessible to Texas DOT employees via the Texas i-Way learning content management system.

Tools for Detective Work

Poor quality construction can occur due to a number of complex and sometimes competing variables, reports the Texas DOT, including reduced inspection staffing, employee turnover, variability of inspectors’ and project managers’ experience levels, incompatibilities between new admixtures and construction materials, implementation of new technologies and construction methods, environmental constraints, recycled materials and other issues unforeseen during design and construction phases.

“To prevent, and to reduce the probability of premature pavement failures and poor long-term pavement performance, the root causes of these problems have to be identified,” Texas DOT says in its Pavement Design Guide. “In conducting forensic studies, a thorough review and analysis of existing quality construction records and tests, nondestructive testing like ground penetrating radar (GPR) and the falling weight deflectometer (FWD) are essential to identify problematic areas and probable causes.”

“When a pavement fails earlier than expected – with early cracking or rutting – we conduct forensic investigations to determine why that happened so soon,” says Timothy R. Clyne, P.E., MnROAD forensic engineer for Minnesota DOT’s MnROAD pavement test facility.

MnROAD – a full-scale accelerated pavement test facility – tests pavement materials, structural designs and construction techniques. It’s unique in that in addition to a low-volume roadway test track that simulates conditions on rural roads, it includes an actual test section of I-94 that carries live Interstate traffic.

“We will do a forensic investigation on good roads to find out what we did right, or what were the conditions that made things go so well with that section,” Clyne says. “But most of the time our forensic investigations are on early failures.” MnROAD also will conduct forensic investigations for pavements throughout the state, either for Minnesota DOT or local agencies.

Cores Provide Clues

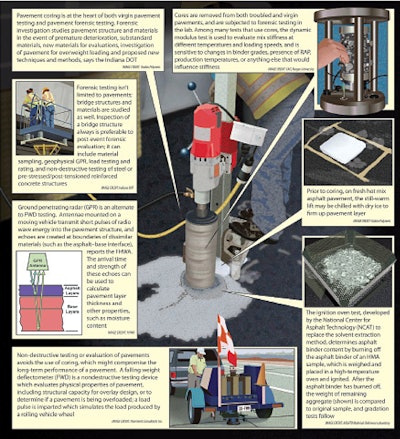

Pavement coring is at the heart of both virgin pavement testing and pavement forensic testing. Forensic investigation studies pavement structure and materials in the event of premature deterioration, substandard materials, new materials for evaluations, investigation of pavement for overweight loading and proposed new techniques and methods, says the Indiana DOT.

Sometimes investigators will use the cores to examine thickness of the pavement structure, or deterioration at the bottom of the structure where water may be present at the interface between pavement and sub-base, eroding pavement support.

Forensic evaluation of pavement failure begins with simple field observations.

Forensic evaluation of pavement failure begins with simple field observations.Cores will reveal if any layer of asphalt has failed to bond to the layer beneath it, or if there has been any stripping in any asphalt layer throughout the core. While pavement forensic testing likely will involve cores taken from troubled pavement, cores from newer or even fresh pavements can reveal trouble down the road.

“Early in a pavement’s life we often will take a core and undertake lab testing or performance testing for rutting, cracking or stiffness,” Clyne tells Better Roads. “We’ll core a fresh pavement to check for thickness, just to verify that it’s what it’s supposed to be. We also will look for asphalt early aging characteristics.”

When cores aren’t enough, extensive sections of pavement may be removed for forensic analysis.

When cores aren’t enough, extensive sections of pavement may be removed for forensic analysis.Coring begins with visual examination of a pavement’s condition. “If you can see a problem at the surface, you can pinpoint exactly where you should take those cores,” Clyne says. “We never just take one core; we take several at various locations, either along one particular crack, several cracks throughout the pavement, or from a strategic grid where we take cores throughout the grid.”

That being said, quite often, the failure area will be small relative to the whole pavement length, or the engineer can choose one representative area of the failure and investigate that small area, which will give him or her an indication of what’s going on throughout the whole project.

But testing of cores often is not needed if careful visual examination will work. “We don’t always test the cores in a forensic investigation; sometimes we just take a look at the cores to give us clues to what’s happening,” Clyne adds. “We won’t test the material properties; we will be just looking to see how the pavement’s deteriorated.”

Visual Examination

Visual examination plays a big role when actual sections – not cores – are removed from pavements. Trenches and test pits cut with pavement saws can remove a larger area of pavement – up to the entire 12-foot lane width – for large samples. Depending on the size of the sample, it may be cut into smaller sections for removal, numbered and then pieced together for review.

GPS-enabled survey vehicle incorporating ground penetrating radar.

GPS-enabled survey vehicle incorporating ground penetrating radar.In these applications, visual examination may suffice. “Your eyes will tell you the story of what’s going in the pavement,” Clyne says. “The simpler the better, we like to say; if a simple tape measure will do, that’s what we will use.”

With visual analysis, investigators will be looking for signs that water has been in the pavement system, and scoured or leached away materials at the bottom of the core or in the core. Are the layers bonded the way they are supposed to be? Are they the proper thickness? If a pavement is a couple of inches thinner than it should be, it’s liable to crack early.

Water damage is indicated by a lack of material. “Portions of the core or pavement won’t be there anymore,” Clyne says. “When the core is taken over a pavement crack, you can see from the edges of the core that the pavement goes down 6 inches, but you will see that the core is missing material where that crack is. It’s just gone.”

“When we have a PCC pavement over a base that doesn’t drain water – an impermeable base – we will see a lot of deterioration and missing material about a third of the way up in that core,” Clyne says. “But for other pavements that drain more readily, cores taken after construction will exhibit joints that are nice and tight and don’t have the deterioration.”

In-service pavement cores also will exhibit unexpected irregularities. “A few years ago we had an asphalt paving job with whole pine cones in the asphalt mix,” he says. “We never were sure how they got there, but we were called to determine how extensive the pine cones were; were they just in one location or distributed throughout the pavement. We went out and took cores, and also made a visual observation of the pavement surface.”

Because Minnesota DOT has a spec that permits up to a certain level of organic materials in a pavement, MnROAD’s forensic evaluation had to determine whether the pavement met the specification, and would the pine cones pose a long-term performance problem. The verdict: The contractor was at fault and took a large deduct.

“A concrete pavement from a few years ago had clumps in the concrete, small balls of unmixed material, aggregates and cement that had not been fully mixed at the plant,” Clyne says. “You could see them behind the paver, small clumps that did not look the way fresh concrete should look. We hired a consultant to evaluate the project by covering every square inch of pavement with ground penetrating radar (GPR). The GPR was able to locate the unmixed clumps in the concrete, and it also found areas where tie bars were missing. The contractor was held responsible to the tune of $1 million.”

Forensic studies don’t just involve tests on fresh pavements or failed pavements; they can involve material samples taken at the time a pavement was produced, and stored. “Pavement forensics for rutting can include in-depth testing of quality control and ‘bag’ samples taken at the time of production,” says Chris Huner, P.E., assistant division engineer – materials, Alabama DOT 7th Division. “There we run volumetric tests and do Abson recovery tests on the liquid binder. We recover the liquid binder from the sample and determine the percent polymer in it if applicable. Then we cut cores from the roadway where the rutting is most severe and compare with the stored samples.”

Closer Look at Materials

Once visual examination of cores is concluded, lab analysis of the asphalt binder, cement paste or aggregates may be necessary to see if the materials confirm the results. A suite of sophisticated laboratory testing devices is available for this analysis.

Lab examination of core displays thermal crack, a problem of HMA mixes in cold-weather regions

Lab examination of core displays thermal crack, a problem of HMA mixes in cold-weather regionsSome asphalt paving projects may begin flushing or bleeding. In this case asphalt will rise to the surface and make slick spots on the driving course. Cores will be taken and asphalt extracted to establish the stiffness of the binder and see if the material placed matches specifications.

For this analysis, a chemical lab will extract a pavement sample from the core, heat it, crumble it and put it through a solvent extraction method using toluene, which strips the asphalt from the aggregate.

That asphalt is recovered by “washing” the toluene out of the liquidasphalt via a vacuum distillation process. This liquid asphalt then is tested in various machines to see if it met the spec.

If that binder is too “soft” it will be revealed by the dynamic shear rheometer(DSR) in the course of a lab investigation. The DSR has two parallel plates, in which one is stationary and the other rotates at a certain amount of strain and frequency (speed). This application is useful in revealing the PG spec of the binder.

The DSR is not the same as the machine used in the dynamic modulus test. This test is used to evaluate mix stiffness at different temperatures and loading speeds, and is sensitive to changes in binder grades, presence of RAP, production temperatures, or anything else that would influence stiffness.

The DSR is a test on binder; the dynamic modulus is a test on the whole mixture, including binder and aggregate. “The dynamic modulus is tested in compression, in which you push or squeeze the material together,” Clyne says. “The dynamic shear rheometer tests shear, in which the sample is twisted. If the DSR gives us the PG rating of the binder, the dynamic modulus gives us the overall stiffness of the asphalt mixture, including aggregate.

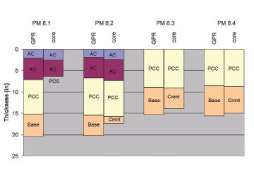

GPR vs. core data (from University of California-Davis)

GPR vs. core data (from University of California-Davis)“In general we’ve been trying to move away from just testing the binder,” he adds. “We want to test the whole mixture, including the aggregate, because that’s what’s happening on the road, that’s what the traffic is rolling on. Binder typically makes up just 5 percent of the mixture – an important part to be sure – but it’s not the only part.”

The dynamic modulus test is not unlike the compression test for portland cement concrete. With the compression test, though, the lab is looking for a failure strength, in which the specimen is broken to bits; the dynamic modulus is tested at much lower loads, in a low strain range, and not tested to failure.

The Asphalt Pavement Analyzer (APA) Rut Tester may predict rutting by exposing mix samples to repetitive loads. It consists of a rubber hose resting on a beam of asphalt, or cores, with a steel wheel that passes over the hose repetitively, replicating the impact of a tire. It is not unlike the Hamburg Loaded Wheel Tester, which uses the steel wheel only. “There is a lot of debate as to which rut tester is more accurate, and they each have their own advantages,” Clyne says. “Most of the time they will rate mixtures similarly.”

The solvent extraction method is one way of measuring asphalt content. The ignition oven method, as developed by the National Center for Asphalt Technology, is a quicker, less labor-intensive method, but it has a limitation.

“If you are looking just for asphalt content in the mix, either one will give you an accurate measure,” Clyne says. “If you want to run an aggregate gradation test afterwards you can run a gradation on either sample. The advantage to the solvent extraction method is that you can test the asphalt as well as the aggregate; the ignition oven quickly burns off all the asphalt so you can’t test it afterwards.”

There is a “green” element to the NCAT ignition oven: The ignition oven does not involve use of polyaromatic hydrocarbons to dissolve the asphalt from the sample, which are perceived to be atmospheric pollutants.

“As recently as 10 years ago we used more harmful chemicals, such as trichloethylene, that could be cancer-causing,” Clyne says. “But we’ve gone away from those to use much safer, much more environmentally friendly chemicals that still extract the asphalt, but don’t come with all the health and safety risks.”

Either way, workers are protected by safety garb, gloves, protective eye wear and fume hoods that pull fumes away from the work area.

Nondestructive Testing

Non-destructive testing or evaluation of pavements in the field avoids coring and section-cutting, which can compromise the long-term performance of a pavement if not done right, and certainly affect ride quality. New technologies make this possible.

“These tools have their limitations but they are very good tools all the same,” Clyne says. “If we can run equipment over the road surface without cutting a core or a trench, and it can tell you what you need to know, that equipment is a very helpful thing.”

The falling weight deflectometer (FWD) is a nondestructive testing device that evaluates physical properties of pavement, including structural capacity for overlay design, or determines if a pavement is being overloaded; a load pulse is imparted that simulates the load produced by a rolling vehicle wheel.

The trailer-mounted FWD will use a plate about a foot in diameter, which drops a load of a known weight on the pavement. Sensors at various spacings around the load plate measure the deflection of the pavement surface from the impact.

On concrete, the FWD can indicate load-transfer efficiency across joints. For all pavements it can test the entire structural capacity of the road, or by using backcalculation, use the raw load and deflection data to determine the stiffness of each of the layers in the pavement system.

“The FWD will not tell you depth,” Clyne says. “You either have to know that from the plans, take cores, or use ground penetrating radar.”

Ground penetrating radar (GPR) is a relatively new, non-invasive, nondestructive pavement testing procedure that will reveal pavement structure data. GPR is an alternate to FWD testing but also may supplement it.

Oklahoma DOT uses GPR to reduce the number of cores required

Antennae mounted on a moving vehicle transmit short pulses of radio wave energy into the pavement structure, and echoes are created at boundaries of dissimilar materials (such as the asphalt–base interface), reports the Federal Highway Administration. The arrival time and strength of these echoes can be used to calculate pavement layer thickness and other properties, such as moisture content.

“Coring may have some degree of effectiveness for specific projects, but at a network level it is costly, intrusive to traffic, and provides very limited samples of the actual pavement structure,” says Dr. Ken Maser, P.E., president of Infrasense, Arlington, Mass.

UST [is] … engineered to detect and evaluate internal reinforced concrete defects

“GPR involves transmitting short radio frequency pulses and receiving echoes from the boundaries between the pavement layers,” Maser says. “The technology has been in use for a variety of highway applications over the past 20 years, and has been adapted for routine use by a number of state agencies.”

The accuracy of the GPR pavement thickness measurements, typically ranging within 3 to 10 percent of core values, has been documented in several university, state agency, and SHRP studies, Maser says. A key advantage of GPR is the ability to collect data at highway speed, using non-contact equipment; typical survey coverage of 200 to 300 lane-miles per day on intercity roads makes this technology well suited for network-level pavement structure evaluation.

Network-level GPR pavement structure assessments have been carried out at the statewide level, as well as by various local agencies and municipalities. At the network level, GPR is now being used for network segmentation into relatively uniform pavement structures, for data inventory input into a pavement management system (PMS) database, and for layer thickness detail for use with network level FWD evaluations.

GPR won’t replace the FWD. For example, Oklahoma DOT has been implementing GPR measurements as part of its ongoing efforts in pavement management to improve its decision making process through enhanced knowledge of its pavements’ structural capacities.

Previously, Oklahoma’s PMS utilized only surface distress data to identify deficiencies at the network level and recommend appropriate treatments. More recently, the state has been acquiring pavement structural condition data using a combination of FWD and GPR measurements on its 2,765 centerline-mile, non-toll NHS system. Oklahoma DOT uses GPR to reduce the number of cores required, to identify changes in the pavement structure, and to provide information for overlay design, says Maser.

“The combination of GPR and FWD data is being exploited by other agencies to identify underlying conditions and to support pavement rehabilitation design,” he adds. “In 2006, Montana DOT acquired a combined GPR/FWD system, and since then has been using the system at a network level to obtain more accurate characterization of pavement structural properties by combining GPR layer thickness data with FWD data.

New on the horizon is ultrasonic testing, the MIRA process. Using ultrasonic shear-wave tomography (UST) technology, it’s a low-frequency (20 to 100 kHz) phased array ultrasonic system engineered to detect and evaluate internal reinforced concrete defects such as honeycombs or voids, and is useful for large concrete structures like bridge components.