We’ve talked recently about the ongoing turf wars between compact track loaders and skid steer loaders. It turns out there’s a third combatant waiting to claim market share: compact wheel loaders.

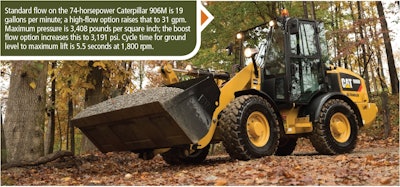

As evidence of this trend, B.J. Meier, product specialist, compact wheel loaders, Caterpillar, says he encourages dealership sales personnel to bring along a compact wheel loader when demo’ing a skid steer. (We define “compact” here as we do in the Equipment World Spec Guide as machines with up to 90 horsepower.)

Not much, for two reasons.

Second, compact wheel loaders are hardly awkward, lumbering beasts. They’re quite nimble. They’re not skid steers, to be sure, but they’re not motor graders, either.

John Comrie, product manager of compact equipment at Volvo CE, says compact wheel loaders traditionally have a much higher rated operating capacity than SSLs and CTLs. The Volvo L20H compact wheel loader, for example, is rated at 4,500 pounds with 64 horsepower, while the highest-ROC skid steers in the current Equipment World Spec Guide, the Gehl V400 and Mustang 4000V, are rated at 4,000 pounds with 99 horsepower.

In addition to claiming market share from skid steers and compact track loaders, compact wheel loaders are also pulling customers from larger wheel loaders and backhoes, says Kelly Moore, product and training specialist with Manitou Group, the parent company of Gehl and Mustang.

Articulation and all-wheel steer

To maximize turning performance and tighten turn radius, manufacturers rely on two design features: articulation and all-wheel steering (AWS).

Brent Coffey, product manager for loaders at Wacker Neuson, says the company’s articulated wheel loaders are the right choice when working in confined areas with tight turns and uneven terrain. Their AWS models have a rigid, one-piece chassis with no articulation, a design that prevents shifts in center of gravity at full turn. Coffey says that with three steering modes – four-wheel, front only and crab – and a 40-degree steering angle on each axle, the AWS machines offer maximum maneuverability and stability.

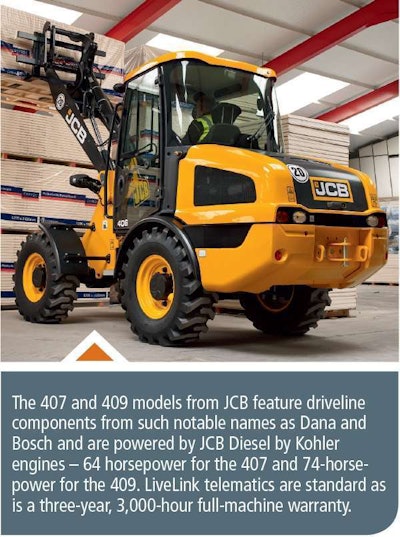

JCB compact wheel loaders rely entirely on articulation. Will Turner, product manager at JCB, says using a fixed rear axle reduces complexity, making service and repair easier. The design also leaves room for a larger cab and lowers the machine’s center of gravity.

The John Deere 244K-II and 324K feature Articulation Plus, where the articulation joint provides 30 degrees of movement and the rear wheels allow another 10 degrees. “This retains excellent maneuverability and a tighter turning radius while providing a higher percentage of lift capacity at full turn,” says Drew Miller, product marketing manager, compact wheel loaders, John Deere. The rear is coordinated steering with no crab steering function. The rear wheels are mechanically coupled to the articulation joint, and rear-wheel steering is proportional to articulation joint movement.

Comrie says that while compact wheel loaders may not have the tight turning capabilities of skid steer and compact track loaders, the characteristics of their maneuverability give them an advantage in loading and placing.

Expanding attachments

Standard on JCB CWLs is a tool carrier front end, which provides parallel lift with forks. A skid steer attachment is available. The SSL coupler is fully enclosed to keep out debris; there are no exposed cylinders or linkages. The bolt-on wear ears can be rotated to maximize service life and can be replaced without replacing the entire hitch. However, the skid steer attachment has more moving parts than the tool carrier front end and sacrifices that system’s low offset (zero offset on the 407 and near-zero on the 409).

Yanmar introduced new compact wheel loaders in January 2017. The 61-horsepower V8 and 73-horsepower V10 are available with a choice of couplers: Schaeff and ISO on both, plus skid steer style on the V8. An optional fourth circuit control with a high-flow function further increases the attachments suitable for use with these loaders. Eric Berkhimer, product manager at Yanmar America, notes that “SmartControl and our multi-function joysticks provide fast and precise control of attachments.”

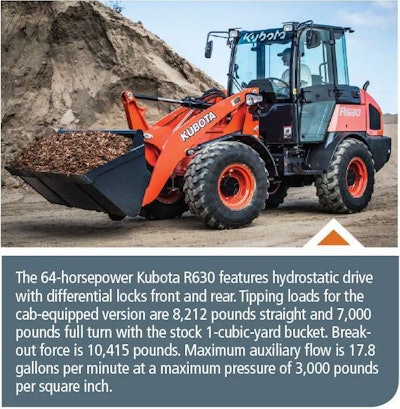

Kubota sought to achieve the best balance with the hybrid link system. Jacobsmeyer says this hybrid design gives the digging power of a Z link with a parallel lift path. “Efficient operation of both the bucket and pallet fork is a huge advantage with this hybrid link system.”

But just because an attachment fits, that doesn’t mean it’s wise to run it on a compact wheel loader. “Not all attachments are recommended or advisable, even if they fit the coupler,” says Brad Stemper, Case product manager, compact wheel loaders. Hammers and breakers lose impact strength because some of their energy is transmitted through a wheel loader’s larger tires rather than through the tool. Saws, stump grinders and anything that requires significant downforce are poor matches. And cold planer performance can be compromised because the tires on a CWL can bounce a bit.

Volvo offers a high-flow option, but Comrie says “high flow” is relative; what’s high for a compact wheel loader is significantly lower than the flow offered by the largest skid steer and compact track loaders. Even so, it’s adequate to run 80 percent of high-flow attachments.

Meier says there’s growing interest for electrical and hydraulic attachments at the rear of compact wheel loaders, as well as rear hitches. Currently, rear attachments consist mostly of spreaders for de-icing chemicals, but more tools will be developed. “Because compact wheel loaders have better rear visibility than skid-steer and compact track loaders, they’re better suited for use with rear attachments.”

Speed, fuel efficiency and other advantages

While compact wheel loaders may concede some performance in the turns, their straight-line speed puts them well in front of skid-steer and compact track loaders. And even higher speed options exist. Rupert Bradley says that high-speed options bump travel speeds to 21 mph on the JCB 407 and to 25 mph on the 409. And with their more forgiving ride quality, compact wheel loaders provide much greater operator comfort at speed.

Joe Boufford, product marketing specialist, New Holland Construction, includes high ground clearance on that list and also says the long wheelbase of a compact wheel loader adds to stability and operator comfort.

Fuel efficiency is often greater, partly because CWLs have lower horsepower engines than competing large skid-steer and compact track loaders. CWLs also usually run at less than peak power, while SSLs and CTLs often run wide open the entire time they work. “Wheel loaders don’t need to operate at or near full throttle to maximize lift capacity and breakout force,” Boufford says.

This difference in engine operating speed also supports a higher percentage of residual value for CWLs, since buyers of used compact wheel loaders know these machines were not thrashed throughout their working hours the way skid-steer and compact track loaders can be. And higher residual value supports the lower total O&O costs for CWLs. Other factors include far lower tire wear and no undercarriage to maintain and repair.

Initial investment is higher for a compact wheel loader; it is simply a larger, heavier machine than a skid steer or compact track loader. The cost difference depends on the basis of comparison. Are you comparing two machines of similar breakout force? Standard bucket capacity? Rated horsepower? The difference may be less than 20 percent or as much as 70 percent.

Comrie points out that CWLs have three to four times longer service life than skid steers. Longer service life coupled with other factors yield total O&O costs of 40 to 50 percent lower for the compact wheel loader.

Compact wheel loaders already have an advantage in reach and lift, and now several manufacturers are adding telescopic booms to their CWLs. The telescopic Gehl T750, projected for release later this year, will have a 16-foot, 6-inch pin height.

Coffey sums up the appeal of compact wheel loaders: “With increased visibility, higher travel speed, additional lift height, telescopic options and skid steer-style attachment interface, the compact wheel loader is the ultimate work machine.”

Have it your way

Other options exist on compact wheel loaders. Stemper says Case offers multiple final drives to match customers’ needs. There’s a limited slip differential (a technology that migrated down from larger loaders), differential locks for loose or challenging conditions and an open differential to minimize tire scrub and surface disruption on improved surfaces.

Case has two styles of service brakes available on the 221F and 321F, traditional outboard wet discs and a caliper-style brake on the output shaft that applies braking force to all four wheels. “The idea is to offer reduced product complexity and service complexity and a lower initial cost.” Other options in the Case lineup include cold-weather packages with a heavy-duty battery, engine block heater and low-temperature hydraulic oil, as well as LED work light packages.

Miller divides Deere CWLs into two groups – the 204L and 304L in one and the 244K-II and 324K in the other. In addition to Articulation Plus steering, the 244K-II and 324K have other standard features, such as a return-to-dig mode and an enclosed cab. The 204L and 304L are offered as simpler, lower-cost machines with limited electronics and an open ROPS cab as standard. “This is in response to customer interest in simpler machines that are easier to service and have lower initial costs,” says Miller. Although the lack of electronics precludes JDLink on these models, features such as ride control are available on all four. Ride control relies on cylinder damping, not electronics. It is on/off on the 204L and 304L, and on/off/auto on the 244K-II and 324K, with the auto mode engaged according to travel speed.