Much of the new is related to the requirement to meet Tier 4 Final emissions standards. New engines. New aftertreatment systems. But this is emissions compliance, after all, and it’s hard to see where there’s a real impact on business. Thankfully, manufacturers have worked hard to bring benefits to the customer while also meeting Tier 4 Final regulations; virtually all of them report fuel savings as part of that benefits package.

Henrik Larsson, product manager with Volvo, says overall fuel use is 4 to 5 percent better with Volvo Tier 4 Final models than with their Tier 4 Interim predecessors. These days manufacturers are left looking for small gains in fuel efficiency, “a half-percent here, a half-percent there,” says Larsson. Much of what Volvo accomplished came from extended passive regeneration intervals of the aftertreatment system on the A35G and A40G models since active regeneration consumes fuel. While daily regeneration was common on Tier 4 Interim haulers, regen intervals now often extend to 500 hours and beyond. The 13-liter engines in the A25G and A30G trucks rely on SCR for aftertreatment and therefore require no regeneration.

Both Caterpillar and Volvo offer a fuel efficiency guarantee. If a customer uses more fuel than Volvo says they will, Volvo writes that customer a check. The numbers used for the basis of the guarantee are quite low, lower even than the numbers published in Volvo’s performance handbook. (Restrictions apply. Learn more at www.VolvoCE.com > Products > Fuel efficiency.) Caterpillar is also reporting fuel efficiency increases of up to 5 percent and details on its fuel efficiency guarantee are available through its dealers.

Doosan says the new DA40 offers 8 percent better fuel efficiency than the MT41 it replaces. In their testing the DA40 consumed 4.5 gallons per hour. Some of that efficiency comes from a new ZF 8-speed transmission, which replaces the 6-speed transmission in the previous truck. The transmission and a revised gear ratio in the differential allow the Scania DC 13 engine to run at a lower speed for a given travel speed while preserving performance. The engine has 11 percent more horsepower and 28 percent more torque than the engine in the MT41 and payload has been increased more than 15 percent from the MT41 to the DA40.

Looking again at the Spec Guides it’s easy to see a steady march toward bigger trucks. In 2008 there were 10 models of 26 metric tons or less; by 2014 that had dwindled to just one, Deere’s 23.2-

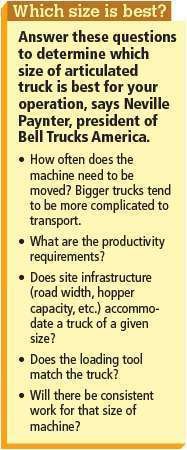

In general the rule is that cost per ton comes down as size goes up. This means that an operation should always buy the biggest machines that it can run effectively. “But these considerations add complexity to what otherwise seems to be a very simple rule of thumb,” says Neville Paynter, president of Bell Trucks America. (See “Which size is best?” sidebar on page 33).