A welder working inside the Macy’s Thanksgiving Day Parade studio. Credit: Bill Delano/USA Today

A welder working inside the Macy’s Thanksgiving Day Parade studio. Credit: Bill Delano/USA TodayTypically, when folks think about the welding, carpentry or engineering careers they likely envision tough a lot of work mastering these respective trades and particular types of environments.

When people choose to go into one of these careers, working in a giant facility filled with massive balloons and ornate floats adorned with dancers in otherworldly costumes and makeup, likely doesn’t fit what they envisioned when they got started.

And yet that’s exactly where some of the best welders, carpenters and engineers end up as the people who build the Macy’s Thanksgiving Day Parade each year. “It’s the best place to work as a craftsman,” painter and head scenic artist Beth Lucas, told USA Today in a recent behind the scenes report by the paper.

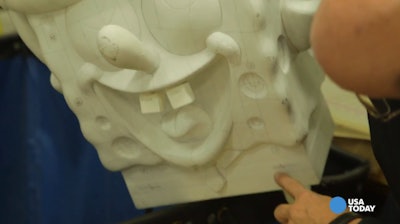

Studio Vice President John Piper shows off a model of the Spongebob Squarepants balloon marked up with schematics. Credit: Bill Delano/USA Today

Studio Vice President John Piper shows off a model of the Spongebob Squarepants balloon marked up with schematics. Credit: Bill Delano/USA TodayThe parade, which started as the Macy’s Christmas Parade in 1924, had its famous floats and balloons made by the Goodyear Tire & Rubber Company from 1927 to 1983. Since then, it’s been a fully in-house production by Macy’s, according to the USA Today report.

The article includes a nice little anecdote from the studio. When recent visitors to the studio asked Studio Vice President John Piper what kind of a “machine” they use to turn planks of wood into the rounded waves on this year’s SeaWorld, he agreed to show them the “machine before turning and pointing to a carpenter on a ladder going over the float for imperfections.

This year, the talented craftsmen built 30 floats and helped in the design and construction of 36 small balloons and 16 huge balloons for the 2.5-mile parade.

When it comes to building balloons, each starts as two scale models made of clay: one is painted to look like the final product while another is marked up with schematics. Using the models as a reference, the pieces of the balloons are cut from a polyurethane-coated fabric and heat-sealed together.

Each year on the Friday after Thanksgiving the studio craftsmen and other workers gather for a Thanksgiving meal since they spend most of the holiday working. But even during that meal they work, talking about the good and bad of the prior day’s parade and making plans for next year’s.

Be sure to read the full report and view a photo gallery at the USA Today website by clicking here.